iPhone 15 Pro teardown shows new camera hardware, A17 Pro chip

The first teardown of the new iPhone 15 Pro confirms it's easier to repair than before, and also reveals how the internal chassis has been redesigned.

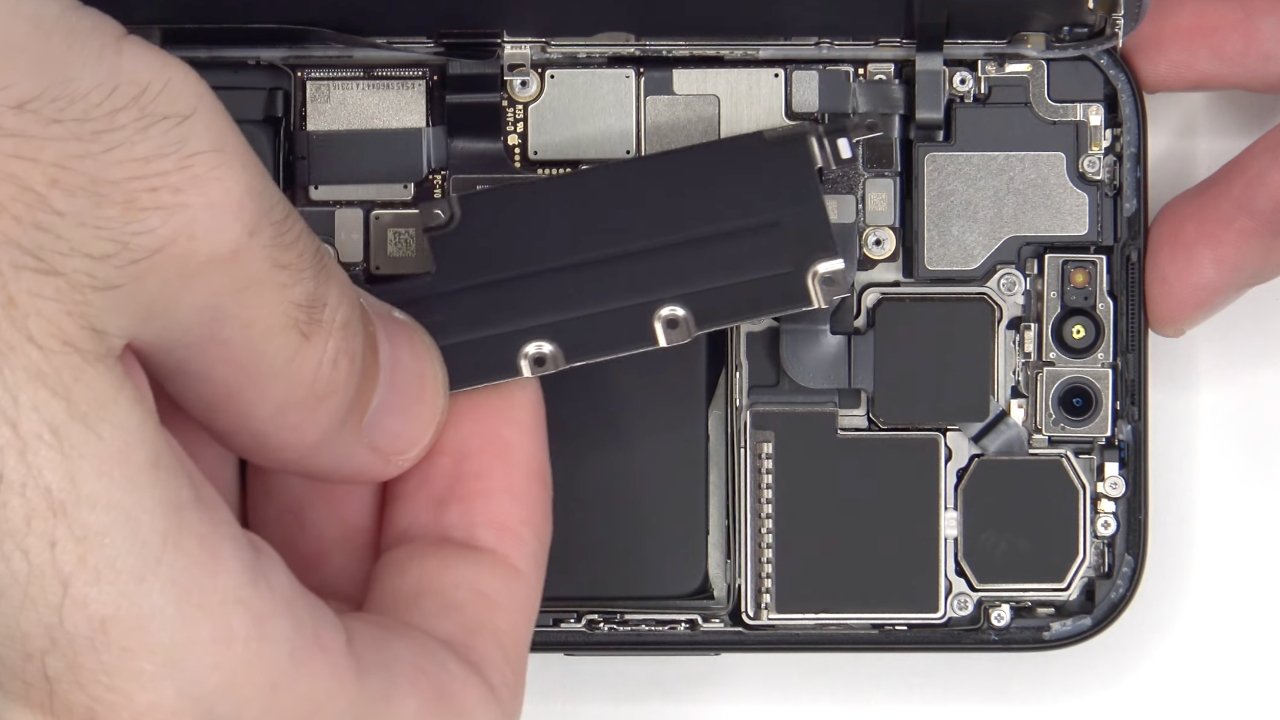

Tearing down the iPhone 15 Pro (Source: PBKreviews)

Every review of the new iPhone 15 Pro has praised Apple for switching to titanium instead of stainless steel. That change means that the iPhones are lighter and stronger, but what gets ignored is that Apple also redesigned the interior.

Now PBKreviews on YouTube has uncovered the details of those internal changes, and demonstrated how in theory the new iPhone is more repairable than ever.

In practice, repairs require more than an ability to take apart and reassemble the phone. Nonetheless, PBKreviews gives the iPhone 15 Pro a repairability score of 7 out of 10.

"And that's if even any of the parts are replaceable," says the reviewer. "When it comes to Apple most parts are locked down, and even if you replace them they're going to pop up some kind of error message or not work properly."

Since around 2019 and the iPhone 11 series, Apple has included a system for verifying that a replacement screen has been done by an authorized repairer. It later extended the idea to repaired cameras, too.

In either case, if a repair does not use genuine Apple-sourced parts, the iPhone will persistently notify the user. It's meant to prevent users being scammed with cheaper, less relable repair components.

The first iPhone 15 Pro shipments to pre-order buyers will start on Friday, September 22, 2023. This is also when the new models will go on sale in Apple Stores.

Read on AppleInsider

Comments

The Pros have 4 cameras (2 with sensor shift modules), LiDAR, IR scanner, dot projector, proximity sensor, induction coils, vibration motor, 2 speakers, 2 microphones, 4 antennas, 4 buttons, USB port, induction coil, and L shaped battery.

The pull tabs supposedly will result in pulling the glue totally out leaving a clean surface. Probably not true all the time and the service tech has to clean, but if done right, it should be a much cleaner process with less solvent touching phone components.

Like with everything, there is probably a procedure to get the pull tabs to come out well every time. Maybe it is having the right temperature, who knows.