Apple's iPhone assembly automation goal has hit some bumps in the road

Thanks to automation, the Cupertino-based tech giant plans to reduce the number of workers assembling the iPhone by as much as half, but that could have disastrous effects on international labor markets.

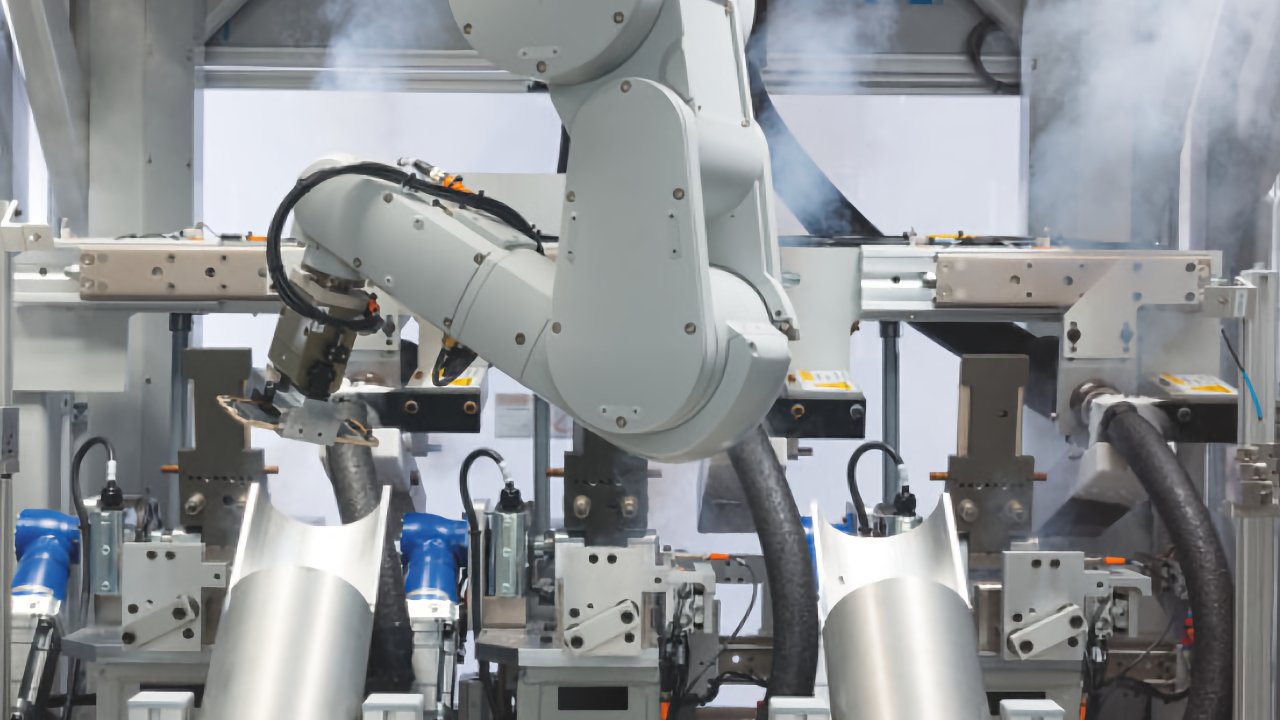

Apple already uses robots, like Daisy, in its device recycling programs

Apple has always known that its business was heavily reliant on workers in its international factories, such as Foxconn, to ensure the iPhone would be ready to ship in the fall.

In 2020, Apple learned just how important they were. The COVID-19 pandemic caused supply chain shortages and delays that the company is likely still recovering from.

And, it learned that lesson again in 2022, when hundreds of workers rioted at Foxconn's main iPhone factory in Zhengzhou, China. Workers alleged that both pay and conditions were abysmal, and videos showing Hazmat-clad police officers beating the protesters surfaced on social media.

According to The Information, Apple's senior vice president of operations, Sabih Khan, had sent an edict telling his managers to "reduce the number of workers on iPhone final assembly lines by as much as 50% over the next few years."

This meant the company would need to resurrect old automation projects it had previously postponed due to high short-term costs. However, the company has since heavily invested in automation, which allegedly was utilized in producing the iPhone 15.

The push for automation reduces the number of workers and, therefore, could theoretically reduce some of the cost of producing the iPhone -- and eventually other products. However, the machines used in automation can cost hundreds of millions of dollars, and many of Apple's manufacturing partners aren't willing to make that investment.

Apple's real reason is to avoid the problems inherent to relying on human workers. After all, machines don't get sick, don't demand better conditions, and don't require the same number of accommodations that human workers do.

Of course, machines can also be installed and operated in areas that aren't in places that aren't actively embattled in US trade-regulation battles, too.

But, according to the report, there have been some issues. Robots used for testing were having difficulty placing small pieces with enough precision, and more with adequate screw placement and proper torque.

The impact on China's labor force

It is unclear what that would mean for China's labor market, which supplies millions of workers to Apple's supply chain. If these workers were suddenly laid off, the effects could be disastrous.

Apple's 2023 supply chain report showed that the company dropped the number of employees it monitors at manufacturing partners from 1.6 million in 2022 to 1.4 million in 2023. That's a reduction of 12.5% in a year and the first time that figure shrank in over a decade.

Apple's automation efforts have been successful in part due to companies it has acquired along the way. In early 2024, Apple purchased Canadian startup DarwinAI, which The Information points out can be used to inspect components like printed circuit boards for defects.

Apple also acquired Drishti, a startup that aims to help manufacturers identify footage of assembly lines to identify bottlenecks in real time.

In 2024, Apple planned to automate the installation of buttons and other components on the upcoming iPhone 16. However, due to a high rate of defects, the company has decided to delay its headcount reduction targets for another year.

Read on AppleInsider

Comments

This is a negative for China, in that as the story states, a reduction in labor will have a negative impact on the economy of China, with a further reduction in consumer consumption.

Now Apple is moving out of China and also adding some automation, which could lead to hundred-thousands of no longer working Chinese and that at a time where PRC unemployment rates are rising!

If Apple pushes for more automation in China, they'll face a mountain of trouble in China. The fact that PRC government started forbidding to carry iPhones for any government worker (in the office) was just a warning shot and already lead to revenue loss in China.

(Now add the convicted felon tRump as #47 and his loud anti-china-rethoric and Apple will face significant headwind in the PRC!)

As labor gets more expensive, and exploited labor looks bad for a company like Apple that cares about its corporate image, shifting more manufacturing to robotic assembly (why not even back home?) is inevitable and a good plan where practical. Diversifying manufacturing to other low cost labor countries like India also makes sense in the short term, but I'm sure we will inherit another set of political problems in most of those places.

It's actually worse than that. Expect a global dislocation in trade as the bulk of trade travels through South Asia, including vital energy and foodstuffs that China relies on. Yeah, not good, but Xi is focussed on himself, not China.

If Google is in fact working with Foxconn to increase automated assembly, that's a good thing.

(Sorry, but you threw that softball right in the middle of the strike zone.)

Anyone born prior to last night or today can see the problem with comparing numbers to numbers without applying the proper context. The assembly line workers are being displaced and replaced by automation. End of story. Those displaced workers are not showing up the Monday after their layoff to start their new job working in the automation business. Automation at any level changes the nature of the jobs that are driving any industry that uses automation, which is basically every business in existence today, from manufacturing to health care to banking, etc. Displacing workers with automation will eventually encompass more and more workers at higher and higher levels.

AI is automation. It very well could be coming for your job. You can see the robots coming, but what about the AI?

I'm not being alarmist, I'm just saying that even back to the Roman Empire automation was recognized as being something that causes worker displacement. Also, automation exists at many levels too, so don't just thing it's some factory of the future staffed entirely by robots and automation. Your dishwasher, clothes dryer, and garage door opener are forms of automation. One of the growth markets in automation over the past decade plus has been automated package machines that do everything from filling milk cartons to bagging potato chips. It's not just the multi acre factories with miles of monorail and conveyors, it's also a plethora of smaller scale automation machinery that can fit in your living room.

Even the very large automated systems are composed of many integrated work cells that work independently on one piece of the puzzle at a time and pass it along to the next one. Some of these individual automated work cells have been around for many decades, like robotic welding machinery and automated guided vehicles (AGVs), and have been working alongside work cells staffed by humans. Of course, keeping the humans away from the robots and automated machinery has always been a very serious safety concern. The fewer humans crawling around, the better, so expect more and more automation and fewer and fewer humans over time. It takes time.

This gradual transition to higher levels of automation has been going on for a very long time, so Apple revisiting how to make automation work for them is not at all unusual. Even Tesla ran into problems early on with too much reliance on automation and had to regress to getting more people on the line. I have no doubt that this reversal will gradually be augmented or completely replaced by even better automation at some point.

As networks get faster, more intelligent and more precise in terms of location, the robots and AI will be able to do more and more. Throw in ZE-IoT, network sensing etc and people become largely unnecessary in the production and distribution process.

There is no point sending an army of workers up pylons to inspect power lines if the same task can be done with drones and AI vision. The same applies to jobs with occupational hazzards like port crane drivers, mining or jobs where repetition is the order of the day.

The EU has been looking at this for decades and has had numerous informal sessions on the idea of a 'universal income' , basically for those living in a society with less job options.

Industrial automation has been around for a very long time. Early systems used mechanical sequencers somewhat akin to the spool with spikes you'd see inside a music box. Relay based systems came later, including one of a kind custom control systems designed for specific machines and specific systems designed by the people who were putting the system together. A really big change came along when automation focused companies, not the product manufacturers, made a series of "standard" automation products that nearly any manufacturer (or an an outside system integrator) could piece together to meet their automation needs.

I quoted "standard" because the standardization was largely limited to one automation equipment supplier. For the most part, everything that an automation equipment provided was proprietary, including connectivity mechanisms between the automation machines and surrounding systems like back office recorders, inventory management, data processing systems, etc. Of course every big automation equipment supplier had their own collection of partners, OEMs, distributors, system integrators, etc., that provided many additional compatible components and services to get systems put together for the eventual customer that owned the automation system. You basically had all of these silos with a relatively low level of integration and interoperability between them. This is very analogous to earlier computing systems, for example IBM. Honeywell, Sperry, DEC, GE, etc.

Just like what happened with the PC market, automation equipment makers started to take advantage of relatively standard ways of connecting things together, like RS-232, serial, RS-422, Modbus, CAN bus, 4-20 mA analog, etc., but they usually layered their own protocols on top of the common physical layers they adopted from the outside. There is still a lot of these proprietary networks in use today. The real breakthrough, imo, is when true industry standards managed outside of the automation industry, especially Ethernet, started to be attractive for use in automation systems. Again, many of the equipment suppliers layered their own protocols on top of Ethernet TCP/IP and UDP, for good reasons in a lot of cases because off the shelf Ethernet with CSMA/CD on 100 Mbps networks wasn't necessarily compatible with performance and throughput needs of the industrial sector. As Ethernet got faster and consortiums of automation equipment suppliers agreed on certain ways to make Ethernet meet their needs (mostly by using UDP exclusively) Ethernet really caught on and gateways between the older proprietary networks and Ethernet became readily available. Sound familiar Thread and Matter fans?

Moving to IP based networking on Ethernet (or a slightly modified version of Ethernet) opened up massive opportunities in terms of connectivity not only within plants and their business systems but to the world. Just like every point of connectivity in the world today, it also exposed these systems to all of the security and privacy concerns that we have been struggling with for more than three decades. Proprietary industrial networks provided a small level of security protection due to security-by-obscurity, but this was blown out of the water when gateways were in the picture and people who live to mess with your world figure out how to get through what you thought was a proprietary network. Anything that wasn't explicitly designed with security as a primary requirement is at risk and will be breached. Industrial and infrastructure cybersecurity is a existential threat to every industrialized country on the planet.

Even today there are known breaches/incidents that have resulted in automation equipment suppliers being required to notify all of their customers worldwide to make sure their systems are not connected to the Internet until the incidents are resolved. While approaches like DMZs and air gapping are widely used in more general computing applications, some players in the industrial sector are little behind the curve, and like I said, if security is added after the fact it's never going to be as secure as when it was baked in. Adding security after the fact usually breaks a lot of existing functionality. For manufacturing and production operations that lose tens of millions plus for each minute of downtime, breakage is never a good thing. But neither are security breaches, ransomware, etc. It seems like every day some large organization, even local government offices and hospitals are victims of ransomware. Fortunately, Industry 4.0 and IIoT have central focus on cybersecurity and is baked in from the start. Unfortunately, getting big new standards related things of any sort into the field can seem frustratingly slow.

Just like every computing system on Earth, there are massive benefits to be realized with emerging technology. Industrial systems are just another computing system. There are also very real risks that must be dealt with, including worker displacement. It's not just assembly line, manufacturing, mining, or manual labor workers that will be displaced by automation. Displacement will happen at all levels. Just like bank presidents and high level officers once performed as tellers, and the teller role was replaced by low wage workers, who were subsequently replaced by ATMs, nearly any job at any level can be replaced at first by lower wage workers, and subsequently by automation. Software developers included. The first phase, outsourcing software development to "low cost" regions has been going on for years. The next phase will be AI and automation, not for everyone, but for many.