New TSMC 1.4nm chip is destined for the iPhone 19

TSMC has confirmed the existence of a 1.4-nanometer process, that will be used to make future Apple Silicon chips starting in 2028.

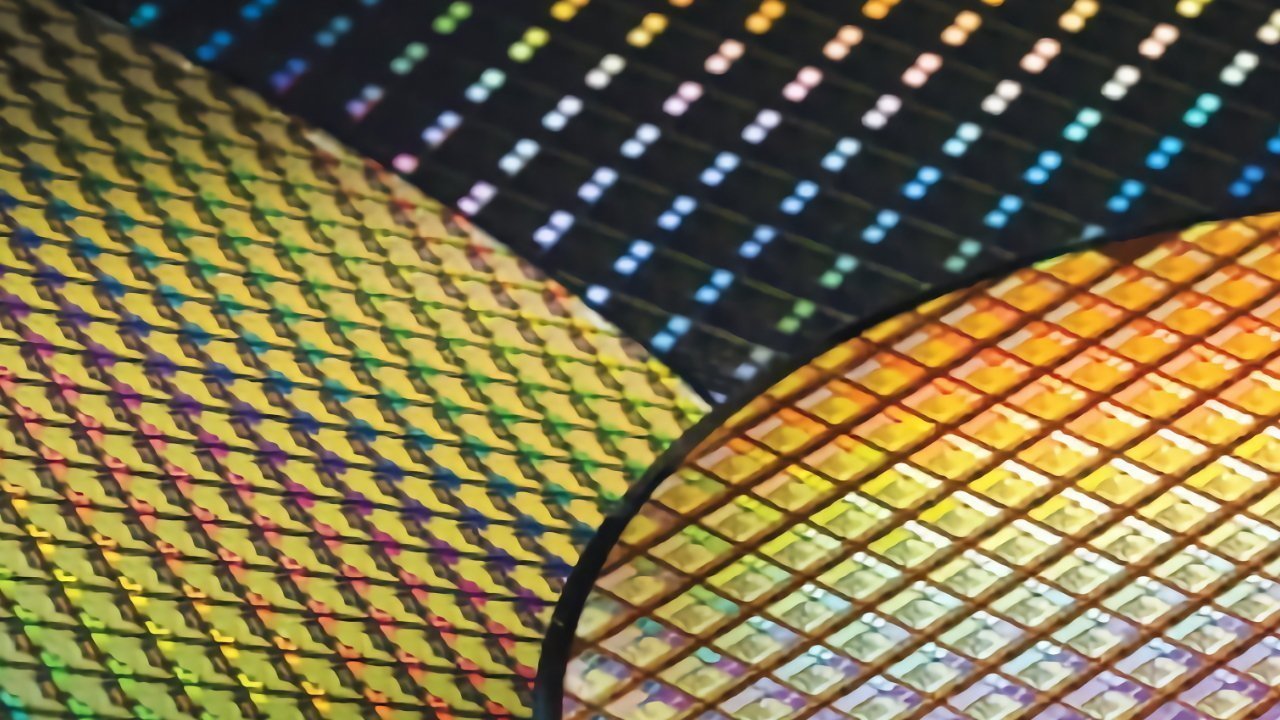

Chips on wafers - Image Credit: TSMC

The performance improvements of Apple's hardware is largely down to improvements in its chip designs, with newer versions getting faster over time. Another component is how the chips themselves are made, which is down to the efforts of Apple chip partner TSMC.

On Wednesday, TSMC used its North America Technology Symposium to unveil its A14 process. An improvement on the 2-nanometer N2 process, the A14 is anticipated by TSMC to help push forward artificial intelligence on servers, as well as on smartphones like the iPhone.

Currently, the N2 process is set to enter volume production later in 2025, and is expected to be used in the iPhone 17 Pro this fall. Compared to N2, the A14 process will provide a 15% speed improvement at the same power consumption rate, or up to 30% in power reduction for comparable performance.

There's also a 20% increase in logic density -- the amount of transistors and miniaturized circuitry it can squeeze into a space.

Destined for iPhone

While TSMC doesn't specify what clients will use a specific announced technology or process, it is certain that Apple will be using it in its future chip efforts. Apple is a major client of TSMC, and uses its newest perfected processes in its A-series and Apple Silicon chips.

Based on TSMC's claim that A14-process chips will enter mass production in 2028, that means the first Apple hardware to use it could be the iPhone 19 generation. Thanks to TSMC's naming choice this time, it could confusingly mean that TSMC will use the A14 process to produce Apple's A21 Pro chip.

That does all hinge on whether TSMC can actually perfect the process in time. Based on TSMC's current assessment of smooth progress in terms of yield performance "ahead of schedule," it seems to be a very likely prospect for the iPhone's future processing needs.

Read on AppleInsider

Comments

2026- 18

2027- 19

so 2028 is the iPhone 20

2025- A19: rumored 3rd gen 3nm

2026- A20: 2nm

2027- A21: A18? 1.8nm

2028- A22: A14 1.4nm chip

No. Intel progressed to a new process every two years for a very long time. The politics of the chip business derailed them for a while. There was a big fight between Intel and the others about what to call a process. For decades, a process size actually meant the size of the features used to make the transistors. Then, as sizes began to get smaller, around the 22 to 14nm sizes, companies found it was too difficult to continuing that, so they made variable feature sizes on a chip, with the narrowest width line defining the process size.

Intel insisted, at 10nm, that all features should be at the 10nm scale. But they couldn’t do it, not unexpectedly. They wasted almost three years trying to do that before giving up. Then they tried, with their process sizes still being better (an Intel 10nm was about equal to other’s 7nm, for example) to use transistors per square mm, but of course, nobody else would agree to that as it put them at a marketing disadvantage.

intel’s problems were caused by other thinks. One of which was Apple’s A series and then their M series, which took interest away from the x86 lines. By the way, while and made a major comeback, they’re in the same boat as Intel.

Real chip nerds don't care about process node names. They look at real metrics like performance-per-watt or performance-per-dollar.

It's similar to vanity sizing in the apparel industry. It really doesn't matter what number (Size 2, Size 4) is on the label, it matters that it fits. And anyone in the women's fashion industry knows that Size 0 in some places is Size 4 somewhere else. It's only relevant to that specific vendor.

Intel didn't lose marketshare to AMD because the process node numbering was a debate. They lost on head-to-head competition. Remember Rocket Lake? Some people called it a "waste of sand".

Joe Consumer doesn't care about A14 or N3P or FinFET or any of that other gobblygook. They see one phone that lasts 15 hours and another phone that lasts 18 hours.

The only thing that really matters here is that TSMC is moving to a smaller process node in the future which has a different name than what's being shipped NOW. As long as they stay consistent within their own nomenclature methodology, there's really little else to be said because companies have been disagreeing with this for years.

And if any given company thinks they are at a "competitive disadvantage" (LOL) just because a letter or a couple of numbers on a marketing e-mail, well, they'd be morons if they didn't adapt to what the competition is doing.

That tracks based on recent experience. We expect the last N3 class iPhone this year, then we can expect 3 years of N2 (2026, 2027, and 2028).

Every time there's a new node on the horizon from TSMC, media outlets breathlessly report that the year the node goes into production as the year Apple introduces a product using that node. That *never* pans out. It's always the year after production starts that we get products available for consumers to buy.