It's still cheaper to import iPhones with 25% tariffs, than assemble in the US

Analyst Ming-Chi Kuo says, perhaps obviously, that Trump's new 25% tariff on Apple shouldn't make the company move manufacturing to the US, because it's still far cheaper to import.

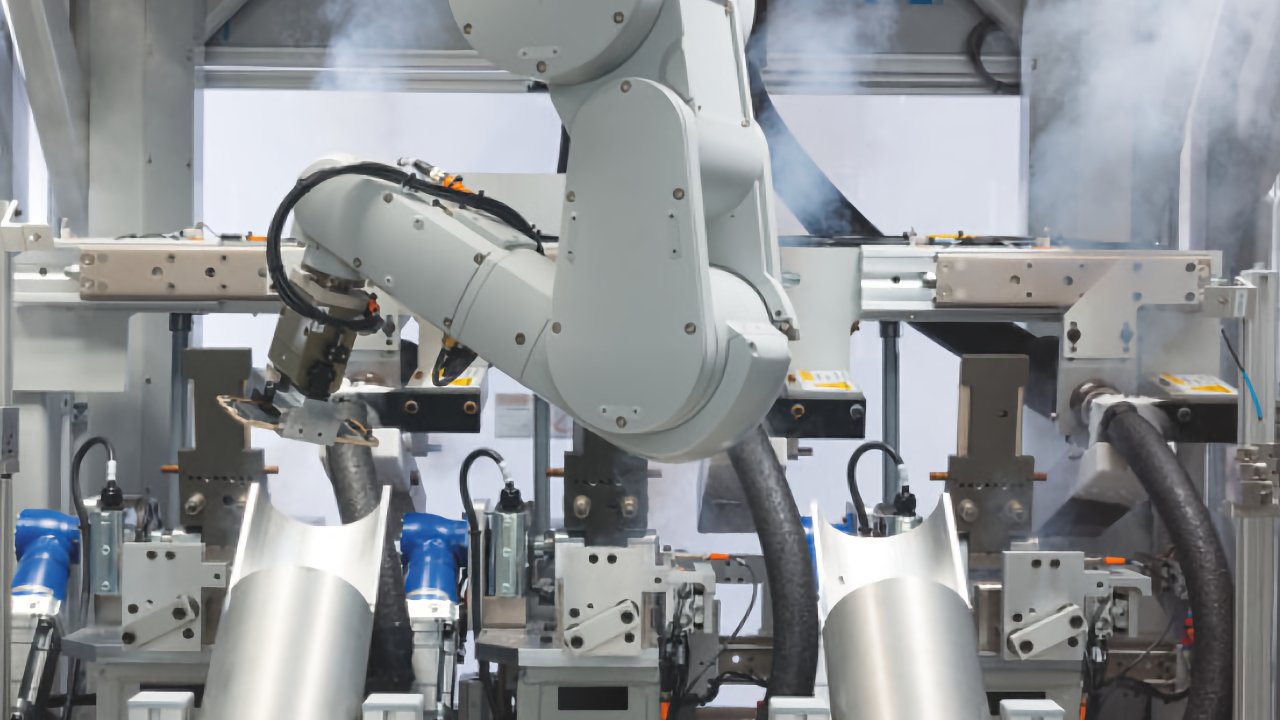

A lack of robots are not the the only thing preventing iPhone manufacture in the US

Trump announced his 25% tariff on Apple's iPhones -- for once specifically naming a US business instead of nonsensically claiming foreign countries would pay -- on Friday, May 23, 2025. It immediately sent Apple's share price tumbling, yet again, but analyst Ming-Chi Kuo agrees with AppleInsider and common sense interpretation of the tariffs about the long-term impact.

In terms of profitability, it's way better for Apple to take the hit of a 25% tariff on iPhones sold in the US market than to move iPhone assembly lines back to US.https://t.co/ycTwPmQyEp pic.twitter.com/VPRRpj0caU

-- (Ming-Chi Kuo) (@mingchikuo)

Kuo goes no further than looking at the immediate bottom line cost, but chiefly because that issue alone is compelling enough. One estimate was when Dan Ives calculated it would cost Apple $30 billion more and take at least three years for Apple to move just 10% of its supply chain to the US.

That $30 billion may be optimistic.

Investment firm Morgan Stanley puts the cost at hundreds of billions of dollars. And TSMC's first two processor factories in Arizona have already cost it $40 billion.

If Trump was serious about bringing manufacturing back to the US, he would be investing in education to train up the immense number of skilled engineers required. Instead, the tariffs are political posturing that will cost Apple $900 million in the current quarter.

Apple can take that $900 million hit, and even though the new 25% tariff on its own will add billions to its costs, the company can surely withstand that too.

Only Apple knows what this tariff will cost them in total, however, since the company does not publish sales volumes. Even if it did, the 25% tariff is on the import price rather than the final retail price.

Then, too, the tariffs are on individual iPhone imports and 25% of an iPhone 16 Pro Max will be different to 25% of an iPhone 16.

Kuo is right that Apple should pay the tariff instead of moving manufacturing to the US. However, if Apple did choose to move, it would presumably still be paying the tariff for each of the many years before US production could possibly begin.

Trump says Apple should manufacture in the US, and he says that his tariffs discourage investment in other countries. Instead, they are solely accelerating that investment in foreign countries.

Apple's recent reorganizing of its supply and distribution chains to minimize the impact of the "reciprocal" tariffs, though, is just the latest in the company's years of maneuvering. While moving away from China is partly about reducing over-reliance on one source, it's also long been about tariffs.

Back in 2018, iPhone assembly firm Pegatron was reported to be moving from China because of trade tensions. By 2024, Apple suppliers had already spent over $16 billion on plans to reshore to places such as India.

Even in the midst of Trump's tariffs, Foxconn is not looking to move to the US, it is planning to double iPhone production in India by the end of 2025.

So the tariffs don't hurt other countries. They just see US businesses taking the hit -- and eventually, passing it on to their buyers.

Read on AppleInsider

Comments

The most feasible way to build an iPhone in the US is to invent a time machine and take control of the global economy in a way that would ensure the US never passes manufacturing to foreign entities.

The iPhone can be assembled in India (a democratic country) and sold in America. And the iPhone can be assembled in Brazil (a democratic country) and sold in America. So that is not the issue. What is happening here is not a choice between products from a democracy or products from a dictatorship. It’s a choice between products from America or products from literally all other countries.

Trump, like China, is definitely not interested in human rights nor democracy.

Cook could just say Fk it and pay the 25% (or additional 25%) indefinitely. It would take years for building a plant to satisfy Trump's whim. No, decades. And that's only if Trump doesn't raise the vig. Cook says Apple can live with 25% and makes no plans to build. Trump would be triggered and probably raise the tariff again if somebody doesn't keep him in check.

What's the answer or is there more than one? I have no idea. Even when he leaves office there will still be a huge mess to clean up and correct. There's no telling how much infamy will live on in the Red Party and celebrated as legacy. I think we're going to see Apple prices get somewhat painful though not impossible (ha!) for most to afford.

Maybe he thinks all the cuts to Medicaid and other programs will create workers who would love a soulless job of assembling electronics for pennies. Soon he will realize that you can bully government officials and vulnerable immigrants, but when you take on large corporations that have the cash to fight his racist xenophobic agenda, that’s another story.

It takes 17 man hours of labor to build 1 iPhone. This doesn't include setup and testing time after it's built.

It takes Tesla 10 man hours hours to build a Model Y. Cybercab will cut this significantly.

Tesla vertically integrated manufacturing, Apple outsourced it to the lowest bidder.

Lastly, Apple builds quality products that last years with excellent fit and finish, Tesla doesn't. They're on the bottom of nearly every reliability vehicle rankings. Get off your Tesla high horse and get into the real world buddy. Maybe if they spent more time designing and building they could have better quality vehicles.