Arms race: Apple's waiting for robotics for US iPhone assembly, says Commerce Secretary

Apple will eventually make the iPhone in the United States, as soon as it has the "robotic arms" to do so, CEO Tim Cook allegedly told U.S. Commerce Secretary Howard Lutnick.

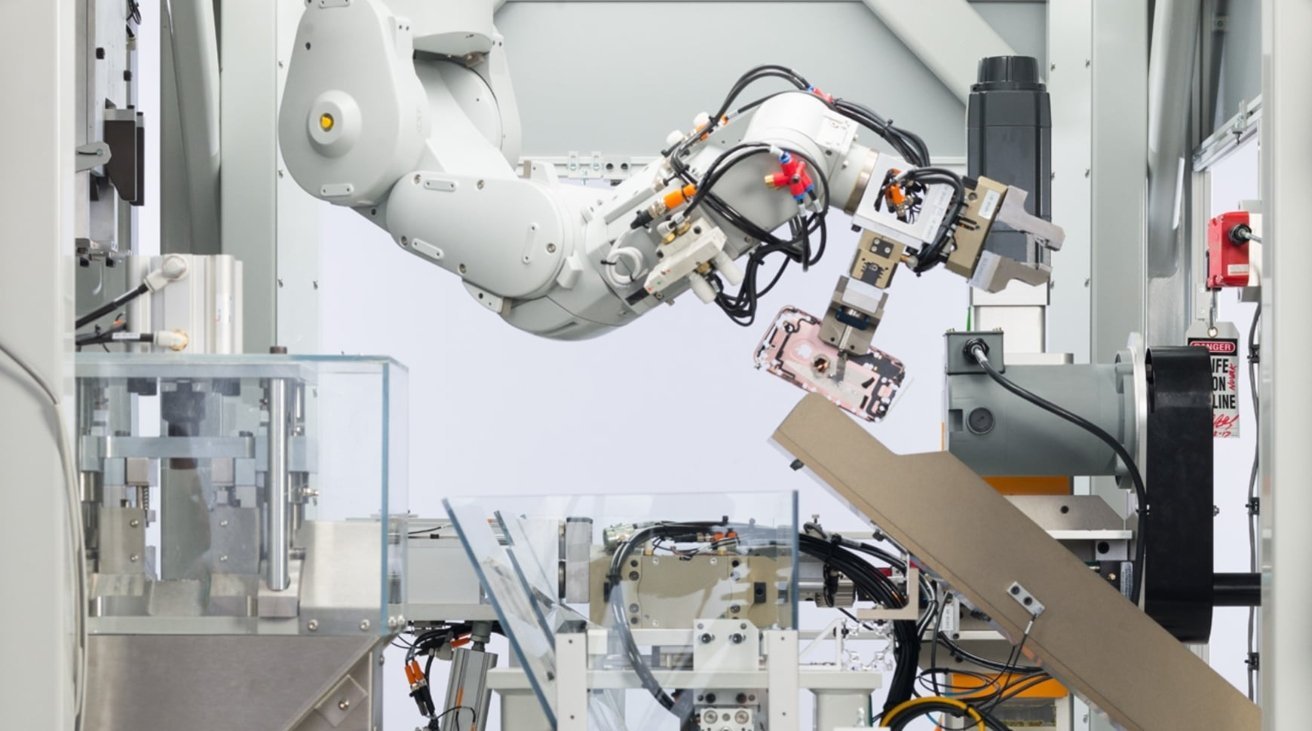

A robot arm used to recycle iPhones, not manufacture them - Image Credit: Apple

The Trump Administration has long held the narrative that Apple will be bringing production of the iPhone to the United States. While the prospect of that happening is still far off, it apparently seems like there's one little obstacle in the way, if U.S. Commerce Secretary Howard Lutnick is to be believed.

Speaking to CNBC on Tuesday, Lutnick was asked about when he expects Apple will make the iPhone on U.S. soil. His response initially raised the pledge by Apple to invest $500 billion in the United States, on practically everything but product manufacturing.

For the iPhone itself, Lutnick recalls an apparently recent conversation with Tim Cook, when he asked the Apple CEO the same iPhone manufacturing query. Cook's reply was straightforward, with him allegedly telling Lutnick "I need to have the robotic arms."

Cook supposedly continued, explaining "Do it at a scale and a precision that I can bring it here, and the day I see that available, it's coming here."

Lutnick added that Cook didn't want to employ an army of workers as that was a risk to the company. Social unrest or a strike in China could harm Apple's manufacturing efforts, the Commerce Secretary detailed.

However, unlike the existing human-centric assembly lines currently in use, Lutnick said that Americans will be the technicians driving the factories. They won't be the ones putting screws into hardware, he insists, but instead will have high-paying jobs as part of a so-called "AI Industrial Revolution."

The screws commentary echoes earlier interviews and statements from Lutnick, in reference to the large workforces Apple partners employ elsewhere.

Solving a U.S. workforce problem

Lutnick's discussion of robotic arms is certainly a meaty soundbite. However, there's no actual confirmation from Apple or Cook himself that the conversation took place, or what the conversational subjects actually were.

Given Cook's proactive attempts to have a working relationship with the Trump Administration, as well as the policies of the administration itself, there probably was a conversation that took place on the topic.

Even so, the actual suggestion of using automation, robot arms or otherwise, is probably the path Apple will have to take to bring iPhone production to the U.S.

Cook has previously commented on the state of the U.S. workforce, including one 2018 discussion about its workings in China. Labour in factories is considered low-cost in the U.S., but in China, Cook views it as a highly specialized task.

Vocational training is promoted more heavily in China than in other countries, which has led to a wealth of world-class tooling engineers built up over decades. It's this tooling skill that runs "very deep" in China, in Cook's view.

It's a skill set that is also not easily transferable to robots, nor can be learned quickly at all. It would require a lot of time, effort, and faith in the U.S. workforce to learn the same skills to a similar level in order to bring manufacturing to the U.S. at scale.

Regardless of whether Apple eventually uses robot arms or the human variety to make iPhones and other products in the United States, it's something that will take quite a few years to become a reality, if at all.

Read on AppleInsider

Comments

Tim Apple isn’t actually waiting for robotic arms to bring iPhone assembly to the United States. Saying “I need to have the robotic arms.” is a kind of diplomatic tech executive way of saying “Sure, I’ll do it… when pigs fly!!!”

Somehow Lutnick thought Cook was expressing a genuine desire. Cook has no plans at all of bringing iPhone assembly to the United States. Lutnick, you need to learn how to read between the lines.

46% being the “reciprocal” tariff rate on Vietnamese goods, which includes their wonderfully-delicious coffee.

I have heard the arguments that automation will increase the number of higher paying jobs versus factory worker jobs. I have seen this to be true over the course of my career. However, it’s never going to be a one for one replacement, not even close.

I suppose the third step is to replace both US based and non-US based workers with automation. I’m not sure how long it will take to go all-in on step three. At some point the huge population of displaced and replaced workers and politicians will likely take action to prevent manufacturing from ending up where it would obviously go if driven by for-profit companies and technologists alone.

"The Important Sound Of Things Falling Apart."

I'm also old and have witnessed the shortage of skilled technical workers first hand for decades. It doesn't seem to be in our educational DNA anymore, and I'm not sure it will change anytime soon, although I wish it would.

I would have thought they would be actively researching given they have shown us disassembly robots which is the same as assembling but can handle less care being taken while you research the precision you need.

Is not ready to deploy the same as “waiting”?