rrrob

About

- Username

- rrrob

- Joined

- Visits

- 12

- Last Active

- Roles

- member

- Points

- 24

- Badges

- 0

- Posts

- 18

Reactions

-

The best video converter apps for Mac

If you want to start working with FFmpeg, I’d recommend looking at ff•Works, née iFFmpeg. It’s a well-done shareware graphical front-end to FFmpeg that makes it easy to use for common tasks by offering a wide number of presets, while making most encoding options available through the GUI and still offering command-line access for the rest. The one caveat is that ff•Works does not include an FFmpeg binary, and one must be compiled or downloaded first. This is actually a feature since it allows ff•Works to switch between multiple FFmpeg binaries as required, e.g., stable, nightly, or custom, without needing to update ff•Works itself. The ff•Works website and documentation point to several precompiled community FFmpeg binaries for downloading to get one started, and the program makes installing and managing the binaries very straightforward.

-

New photos show prototype board used to create original iPhone

Looks legit. Reminds me of the mortables (sic—that’s what we called them) Motorola used at the time for the same reasons. The other reason for the exploded nature of the board was that initial bring-up of the hardware might involve adding jumper wires and making component changes to correct for errors in the preliminary schematics. Much easier to perform when almost every circuit trace isn’t buried in the board beneath the tightly spaced components as they are in the finished product!

-

Google's Pixel 2 XL priced higher than Apple's iPhone 8 Plus but is half as fast, lacks ma...

There are pros and cons to both the Moto X and Apple circuit board designs. TL;DR—in my opinion, they reflect their companies' respective economic situations, i.e., Apple can afford to use a smaller circuit board because it's making a premium-tier product with a high profit margin, and because that product sells in high volume.tmay said:

Strictly speaking, none of the above is industrial design, albeit the industrial design of the external package has a great influence on these circuit board designs, especially at Apple.Soli said:At least the Pixel phones have a better industrial design than the Moto X.

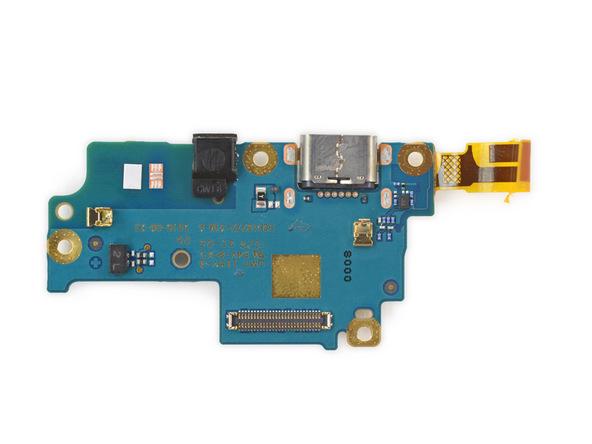

Well, the daughter board of the (HTC) Pixel is still poorly designed and archaic compared to what Apple has been doing since the start of the iPhone.

In case you don't you don't look at teardowns here's the iPhone 8 logic board for comparison. Can you spot the difference?

Moto X Pros:- (Mostly) single-sided. The vast majority of the parts can be attached to the board in a single pass through placement and reflow (soldering), putting less thermal stress on the components. It also provides additional volume for the battery under the circuit board and better physical isolation of RF-sensitive circuit blocks.

- Slightly more surface area, even given the single side used for most parts. This permits the use of larger and easier to place—and hence, cheaper—components. It could also act as a larger heat sink for heat dissipation.

- Fewer board layers. A number are still needed to accommodate pinout from high pin density parts like the Snapdragon, but there's more area to work with on each layer to route traces. And fewer layers make for cheaper panels.

- Good balance of the phone in the hand is easier to achieve since the mass of the battery and circuit board are more evenly distributed across the surface of the phone.

- Fewer circuit boards per panel. This means a greater number of circuit board panels must be processed to build an equivalent number of circuit boards, which could reduce factory throughput. The effect this has on price per circuit board is unclear without knowing the exact stack-up of the Motorola and Apple boards.

- Double-sided panel with tightly packed components enables an incredibly small circuit board. More boards per panel means better factory throughput. The narrower the board, the more volume that's available for the battery, too.

- Doubled-sided. Two major passes through component placement as well as reflow required.

- Intra-board trace layout must be a nightmare. There are hundreds of traces coming out from the pins of the A11 alone which much be routed to memory, SIM, Lightning connector, cameras, display, Touch ID, etc. This also complicates resolving RF desense issues during development (as in, "Why can't you just move that part/trace/via over there?")

- More board layers to accommodate the traces for those high pin density components like the A11. More layers equals higher cost circuit board panels.

- High part density and small components necessitate high-precision solder masking and part placement, i.e., newer, more expensive factory equipment. Heat dissipation also becomes more of an issue.

- Phone balancing becomes trickier with the circuit board and the battery side-by-side.