New MacBook Air and Mac mini are first with enclosures produced from 100-percent recycled ...

Apple is continuing to push forward in its attempts to improve the environment by making the 2018 MacBook Air and the 2018 Mac mini the first Macs to have a casing produced completely from recycled aluminum.

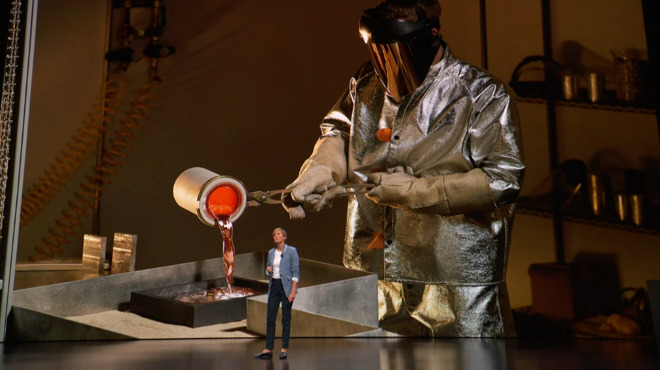

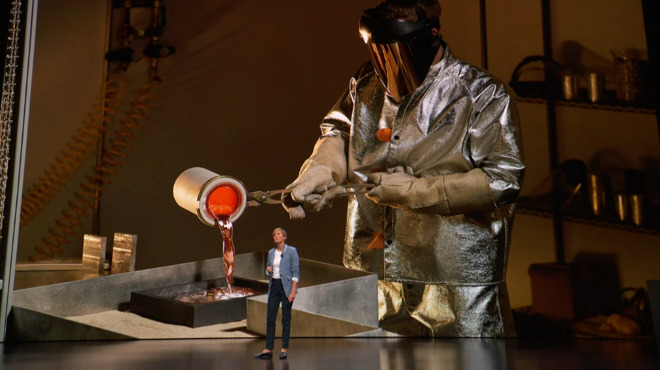

Apple's Laura Lagrove announces the use of 100 percent recycled aluminum in the MacBook Air and Mac Mini

Announced during its Tuesday special event, the unveiling of the new MacBook Air featured the change in material as one of a number of other improvements to the notebook's design that makes it the most environmentally friendly Mac ever. Not long after, the announcement of a new Mac mini revealed it, too, would use recycled aluminum in its construction.

Earlier MacBooks relied on new ore for the production of the unibody casing. Apple's metallurgy team created a new alloy that allowed for the use of recycled aluminum, and without requiring the introduction of new ore. The new process uses fine shavings of recaptured aluminum, partly acquired as excess material from the production of other parts and devices like iPad Pro, with the shavings refined to the atomic level for the new enclosures.

The process is also more environmentally sound and reduces the carbon footprint for the alloy's creation by 50 percent compared to the previous process.

The unibody alloy is not the only environmentally friendly change made to the MacBook Air. The new model also uses 100 percent recycled tin in the logic board, and 35 percent post consumer recycled plastic in other components, including the speakers.

AppleInsider will be at the fall "There's more in the making" event, where we expect new iPad Pros, and maybe even new Macs! Keep up with our coverage by downloading the AppleInsider app for iOS, and follow us on YouTube, Twitter @appleinsider and Facebook for live, late-breaking coverage. You can also check out our official Instagram account for exclusive photos.

Apple's Laura Lagrove announces the use of 100 percent recycled aluminum in the MacBook Air and Mac Mini

Announced during its Tuesday special event, the unveiling of the new MacBook Air featured the change in material as one of a number of other improvements to the notebook's design that makes it the most environmentally friendly Mac ever. Not long after, the announcement of a new Mac mini revealed it, too, would use recycled aluminum in its construction.

Earlier MacBooks relied on new ore for the production of the unibody casing. Apple's metallurgy team created a new alloy that allowed for the use of recycled aluminum, and without requiring the introduction of new ore. The new process uses fine shavings of recaptured aluminum, partly acquired as excess material from the production of other parts and devices like iPad Pro, with the shavings refined to the atomic level for the new enclosures.

The process is also more environmentally sound and reduces the carbon footprint for the alloy's creation by 50 percent compared to the previous process.

The unibody alloy is not the only environmentally friendly change made to the MacBook Air. The new model also uses 100 percent recycled tin in the logic board, and 35 percent post consumer recycled plastic in other components, including the speakers.

AppleInsider will be at the fall "There's more in the making" event, where we expect new iPad Pros, and maybe even new Macs! Keep up with our coverage by downloading the AppleInsider app for iOS, and follow us on YouTube, Twitter @appleinsider and Facebook for live, late-breaking coverage. You can also check out our official Instagram account for exclusive photos.

Comments

edit: So it's the 3rd most common element in the crust at 7% (the most common metal, as you stated), but we get it from Bauxite, which looks to be only contain about 15–25% aluminum. To me, it seems like a good move to recycle it… even if I was scratching my head at why the attendees were that overjoyed by so much about it during the event.

My understanding from the Keynote was that they used iPad shavings.

As for why work to conserve a resource we're in no danger of running out of ... there's aluminium and then there's industrial-grade aluminium. Same material but very different in its properties and strength. Less energy to make, likely to be a lot cheaper to make, just as good (for these purposes) ... why not do it?

Apple is actually being very misleading here as aluminum has always been recycled. In fact I’m not sure if the foundries even bother to indicate the percentage of recycled material in the melt. The reason Aluminum is so highly recycled actually has nothing to do with the environment but rather costs Producing Aluminum from raw ore is very expensive compared to reprocessing scrap aluminum. For some materials like glass recycling doesn’t always make sense.

In any event this has the feel of Apple embracing a common practice to appease a few nut cases. Recycling is good, I just don’t see much to impress in Apples comments here.

I might point out out that I worked in a zinc die wet foundry 3.5 decades ago and everything got recycled back then. If the condition of the alloy was good and known it went back into the pot. If it wasn’t good it went back to the smelters. Pretty much standard industry practice many years ago. Aluminum foundries ran the same way as we had a large number of employees from a closed down facility. I’m not sure what Apple is up to with this claim, I don’t want to call it bogus but this is not something new.

I really dont don’t have much confidence in what Apple is saying here. They may have created a new alloy but that has very little to do with recycling as they described.