Apple may have a solution for fraying Lightning cables

If you've ever had an iPhone Lightning cable in your car, you already know how fragile they are. Apple may now have a solution that could also protect any kind of cable.

This is what happens to Lightning cable all the time

Apple is never going to say that Lightning cables have a death wish, but it has come close in a newly revealed patent application that is really about fixing the problem. "Cable with Variable Stiffness," does not mention Lightning once, nor does it say anything approaching the word "frayed."

"It is well known that bending of the cable near the termination point may cause unwanted strain on the wire connections, which may lead to cable failure," it admits. "Accordingly, it is common to provide a strain relief sleeve made of a stiff material around the end region of the cable."

Apple's descriptions apply to many types of cable, and so do its criticisms of current solutions.

"The stiff material creates a localized increase in the bending resistance of the cable, thereby relieving strain on the wire connections," it continues. "In addition to making the cable locally stiffer, the strain relief sleeve also makes the cable thicker at the ends. In some instances, the added thickness may not be desired."

If you've been using Apple gear for long enough, you may remember how Apple slightly thickened Lightning cables. It presumably meant they were a little less prone to damage. As a side-effect, it meant that they sometimes no longer fit in channels machined into iPhone stands by third-party manufacturers.

Apple's new proposal is a development of both the "strain relief" idea, and the extra thickening of cables overall. "A cable can include a cable core surrounded by an outer sleeve having a uniform thickness," says the patent application.

"[It further has] a first longitudinal section having a first stiffness (e.g., corresponding to a flexible cable), a second longitudinal section having a second stiffness (e.g., corresponding to a rigid cable), and a third longitudinal section between the first and second longitudinal sections," says Apple.

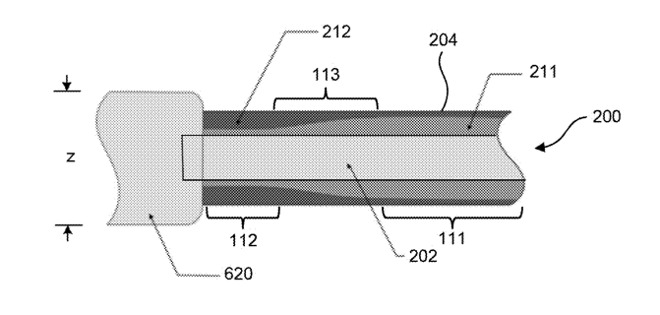

Detail from the patent application showing one combination of layers of cable and protective covering

The first cable has some unspecified certain degree of stiffness, while the second is more stiff. And the "stiffness of the third longitudinal section varies between the first stiffness and the second stiffness." Really what this does is extend the "strain relief for the cable."

The majority of the patent application describes different possible materials, and also attempts to define stiffness. "For example, minimum bend radius, defined as the smallest radius at which the cable can be bent without a kink, is one well-known measure of cable stiffness," says Apple, "and a minimum bend radius can be defined relative to the cable diameter."

"Increasing bend radius corresponds to increasing stiffness. Depending on the particular cable design, the minimum bend radius might be e.g., 8 to 12 times the cable diameter," it continues.

The patent application is credited to seven inventors, including Christopher S. Graham. His previous related work includes granted patents regarding "shielding for multi-coil wireless power transfer systems," and "wound housings for electronic devices."

This is what happens to Lightning cable all the time

Apple is never going to say that Lightning cables have a death wish, but it has come close in a newly revealed patent application that is really about fixing the problem. "Cable with Variable Stiffness," does not mention Lightning once, nor does it say anything approaching the word "frayed."

"It is well known that bending of the cable near the termination point may cause unwanted strain on the wire connections, which may lead to cable failure," it admits. "Accordingly, it is common to provide a strain relief sleeve made of a stiff material around the end region of the cable."

Apple's descriptions apply to many types of cable, and so do its criticisms of current solutions.

"The stiff material creates a localized increase in the bending resistance of the cable, thereby relieving strain on the wire connections," it continues. "In addition to making the cable locally stiffer, the strain relief sleeve also makes the cable thicker at the ends. In some instances, the added thickness may not be desired."

If you've been using Apple gear for long enough, you may remember how Apple slightly thickened Lightning cables. It presumably meant they were a little less prone to damage. As a side-effect, it meant that they sometimes no longer fit in channels machined into iPhone stands by third-party manufacturers.

Apple's new proposal is a development of both the "strain relief" idea, and the extra thickening of cables overall. "A cable can include a cable core surrounded by an outer sleeve having a uniform thickness," says the patent application.

"[It further has] a first longitudinal section having a first stiffness (e.g., corresponding to a flexible cable), a second longitudinal section having a second stiffness (e.g., corresponding to a rigid cable), and a third longitudinal section between the first and second longitudinal sections," says Apple.

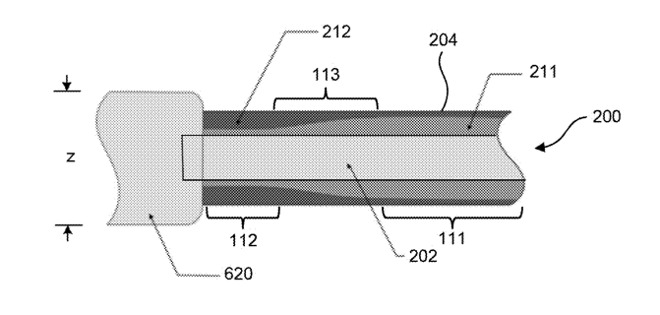

Detail from the patent application showing one combination of layers of cable and protective covering

The first cable has some unspecified certain degree of stiffness, while the second is more stiff. And the "stiffness of the third longitudinal section varies between the first stiffness and the second stiffness." Really what this does is extend the "strain relief for the cable."

The majority of the patent application describes different possible materials, and also attempts to define stiffness. "For example, minimum bend radius, defined as the smallest radius at which the cable can be bent without a kink, is one well-known measure of cable stiffness," says Apple, "and a minimum bend radius can be defined relative to the cable diameter."

"Increasing bend radius corresponds to increasing stiffness. Depending on the particular cable design, the minimum bend radius might be e.g., 8 to 12 times the cable diameter," it continues.

The patent application is credited to seven inventors, including Christopher S. Graham. His previous related work includes granted patents regarding "shielding for multi-coil wireless power transfer systems," and "wound housings for electronic devices."

Comments

I have repaired a couple at the office using heat-shrink sleeving to provide extra strain relief. Works fine, cheap and easy to do.

Great if Apple is looking at the problem but this is an industry problem, not just an Apple problem. So stop with the “Apple cables are crap” nonsense. They are no better or worse than others when the user yanks, bends, twists or otherwise abuses a cable.

The issue with these cables is, that Apple in its drive to be environmentally sound uses a plastic insulation that’s not resistant to sweat/oils from the fingers.

Where you touch the cable, is first discolors, and then the insulation gets soft, gooey, and crumbles.

I treat all my gear very carefully. And I have all sorts of cables, incl. varying quality third party USB and lightening cables, and the problem is unique to Apple, because they are trying to use environmentally friendly plastic, which of course backfires, because if you stick to Apple’s cables, you’ll have to buy several over a product’s life span, rather than one.

Still got perfectly fine “hockey puck” power supplies and cables, old Apple USB cables, etc.; they’re all fine because they’re made from PVC or something similar, while the new *-free cables just crumble over the course of some months on their own after being touched by bare fingers with sweat and finger grease on them.

By classifying these cases as wear and tear and not replacing them under warranty, Apple has in essence prevented that their materials engineers got the proper feedback on one of the main the causes of these issues: It’s chemistry, not physics!

Also, I think cables fray like that because people do not pull the cable out on the hard plastic connector, but the bottom of it (and plastic of course wears over time).

I've never had an Apple cable fail, all the way back to the original cable for the 1st gen iPhone. My wife has had 2-3, but that's clearly her fault. She used to use an iPad, with the cable plugged in, and rest the cable/iPad on her stomach, sharply bending it. Also in her car - the armrest has a notch for cables. She often closes the armrest & pinches the cable.