Apple's $100 billion investment has almost nothing to do with US iPhone manufacturing

Apple's latest announcement of a further $100 billion investment in US manufacturing is a positive, but it still has incredibly little to do with reshoring iPhone assembly.

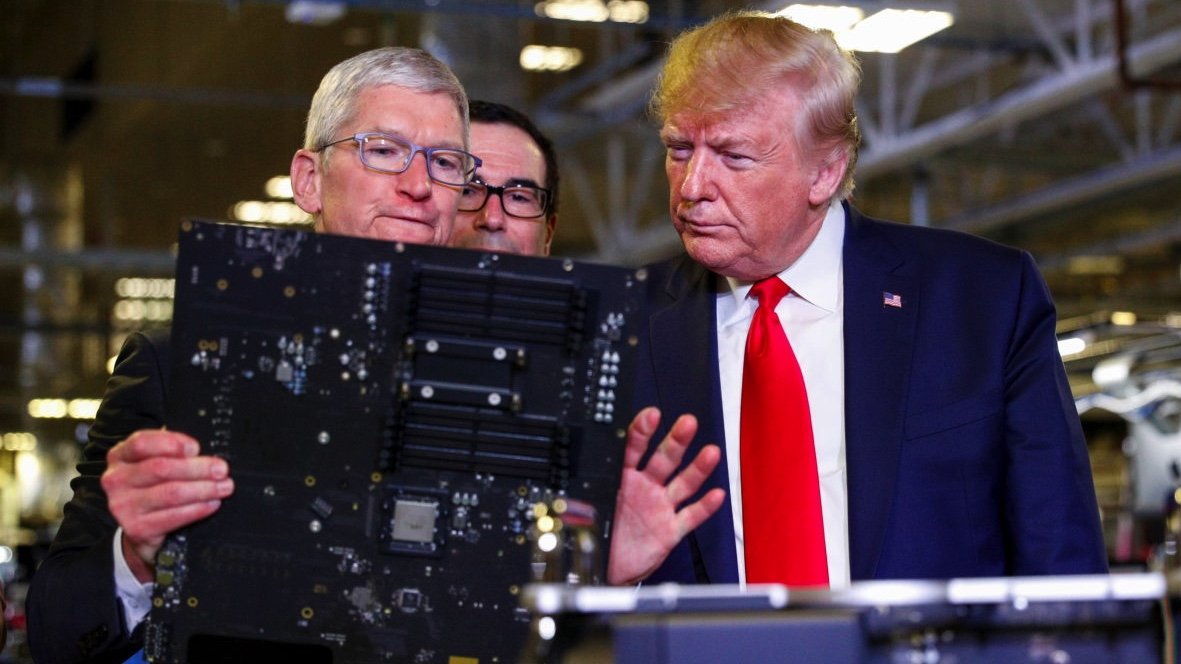

Tim Cook and Donald Trump, at the Mac Pro factory

The expected announcement of Apple investing more in the US comes after extraordinary pressure from Trump to make the iPhone in the States. But it wasn't about making the iPhone in the US -- because it cannot be.

Returning iPhone production to the US would ultimately benefit the country, and it would start undoing the decades of all manufacturing leaving America. It's also very unlikely to happen in a decade, much less the handful of years that the Trump administration wants it to.

Let's be perfectly clear, because we've been criticized because we're looking at these efforts critically, and realistically. AppleInsider wants to see more US manufacturing happen just as any other US business would.

So far, though, Trump's moves and Apple's counter-moves are chiefly smoke and mirrors.

Wednesday's announcement was a lot of money. It's also headed to Apple's existing suppliers, and is spin, and more smoke. It will also extend past Trump's final tour as President.

And, after listening to President Trump's remarks, there's a willful blindness from the administration as to what it will take to get iPhone manufacturing in the US to actually happen, instead of just minor accessories, Gorilla Glass, and the like.

What really needs to be done

It's not enough for a President to say "we want iPhone manufacturing in the US," and it's not enough to just throw money at buildings and factories.

If Trump were serious about trying to get companies to move back to the US, he would be funding the education at all levels that such a move absolutely requires. To its credit, Apple itself is trying exactly that with its Apple Manufacturing Academy in Detroit.

But that academy, at least at first, is a two-day event with a limit on how many people can attend. This manufacturing initiative needs nationwide, government-scale education reform, it needs it over the long term, and it needs to persist across administrations with the same goal in mind.

There is not one single sign of it even starting.

If it did, if education were actually properly funded in the US, it's been estimated that it would cost Apple $30 billion and take three years for it to move the smallest parts of its iPhone operation back to the States.

To be clear, that's moving any part of it. Not even remotely the whole production, which would instead take, charitably, a decade.

It would also take a change in the finances of US manufacturing because US labor costs are now much higher than in other countries. "Made in the USA" with a waving flag looks great on a TV ad, just ask marketers that shill knives on TV at 2AM. Just ask Trump Mobile.

But, that flag is costly at the marketplace.

Buyers complaining today about a possible $50 price hike for the iPhone would have to get used to a much more expensive US-produced device. Bank of America estimated in February 2025 that iPhone prices would rise around 10% just because of tariffs, not because of making the iPhone in the US.

In April 2025, CNBC reported on estimates that a made in US iPhone would need to retail for around $3,500. We don't think that a US-manufactured iPhone will cost that much. But, we don't think a $2000 non-folding base iPhone model without storage upgrades isn't out of the question.

Let's talk about Wednesday's announcement

We're just going to put this here. It's pretty great news for Corning.

Today, Apple is awarding $45 million from its Advanced Manufacturing Fund to Corning Incorporated, a supplier of precision glass for iPhone, Apple Watch, and iPad. The funding will expand Corning's manufacturing capacity in the US and drive research and development into innovative new technologies that support durability and long-lasting product life, building on both Apple and Corning's deep commitment to protecting the environment.

Corning has already received $450 million from Apple's $5 billion Advanced Manufacturing Fund over the last four years. Apple's investment helps support more than 1,000 jobs across Corning's US operations in Kentucky and other facilities. The investment has also helped facilitate research and development into state-of-the-art glass processes, which led to the creation of Ceramic Shield, a new material that is tougher than any smartphone glass.

That sounds great, right? It really was.

It was the announcement made not on Wednesday, but in 2021.

This is Wednesday's bit about Corning.

Apple and Corning today announced a major expansion of their long-standing partnership to make precision glass for Apple products. Apple is making a new $2.5 billion commitment to produce all of the cover glass for iPhone and Apple Watch in Corning's Harrodsburg, Kentucky, manufacturing facility.

This means that 100 percent of the cover glass on iPhone and Apple Watch units sold worldwide will be made in the U.S. for the first time. Since the creation of Apple's U.S. Advanced Manufacturing Fund in 2017, Apple has invested nearly $500 million in Corning's Kentucky operations, with billions more spent on glass manufactured in the U.S.

This is better for Corning, of course. It's cool that 100% of iPhone and Apple Watch glass will be made in the US -- but as far as we can tell, about 90% of it is made in the US now.

It's also the only new project that will expand what Apple is doing manufacturing-wise in the US. The Houston AI plant has already been announced. The data center efforts have already been announced. The manufacturing academies have already been announced.

All the rare-earth reclaim plants have been announced. The only announcement that was new, was Corning, and the trajectory for that was clear anyway.

About 5% of components that go into an iPhone, including Gorilla Glass, come from the US prior to Wednesday's announcement. This isn't going to change much, if at all, by Wednesday's announcement.

Apple is willing, or keeps saying it is

This latest announcement of a further $100 billion is a sign of Apple playing politics, because it has no choice. It is not a sign that Apple is against moving production back to the US, the company just knows it is physically impossible in the short term, so it does what it can to appease Trump.

As far back as 2012, long before Trump was in office, Tim Cook was asked whether there could be an Apple factory in the US again. "I want there to be!" he said, "I want there to be!"

"But look, how many tool-and-die makers do you know in America?" he continued. "I could ask them, nationwide, to come here tonight and we couldn't fill [a few hundred seats in] this room."

That's just gotten worse since.

At various times since, Cook has also questioned an assumption that Apple uses Chinese firms because they are cheaper than US ones. He's said that if this were ever true, it isn't anymore, and it is explicitly the skilled labor force that makes firms use China.

Perhaps as such a large manufacturer, Apple has contributed to the decline of US industry at the behest of all US administrations for 20 years, in service to the all-mighty dollar. But for all that Trump has been criticizing Cook over making iPhones in India, Apple's current CEO is more publicly backing US ventures than his famous predecessor.

For just a year before Cook said that about wanting Apple factories in the US, Steve Jobs was much more blunt. Speaking to President Obama in 2011, Jobs reportedly was blunt stating that "those jobs aren't coming back."

He said it for all the same reasons that remain true today. Nothing happened back in 2011 to prepare the US for manufacturing under a different party, nothing happened during the first Trump administration, nothing happened during the Biden administration, and the Big Beautiful Bill in 2025 actively made the situation worse, from an education funding standpoint.

As long as Trump does little more to assist other than sitting next to big-tech CEOs at the White House, he can continue to push the very easy political point that he's trying to so hard, and can beat the drum that it's Apple who is refusing to do what it should.

It's always easy to blame Apple because it is so big, and because there's rarely much it can do to effectively protest back. And Apple generally doesn't care what politicians say about it.

But in this case, blaming Apple is also way to focus attention on this one company, when in reality there is not one single electronics manufacturer that is able to cost-effectively move back to the US. Foxconn's debacle in Wisconsin is a prime example. TSMC in Arizona is a gesture in the right direction, but because of Taiwan law at the very least, will always be at best three years behind its own domestic production.

At least, though, Tim Cook is publicly more keen on reshoring manufacturing than the do-no-wrong Steve Jobs was. And at least there's Apple's Manufacturing Academy, which may be a pinprick rather than the solution that's needed, but it is a start.

Read on AppleInsider

Comments

So where there’s a will, there’s a way… see how the British converted the millennium dome into a giant COVID hospital so quickly, or built a tunnel under the sea from the UK to France when they were told it couldn’t be done.

several times but no one describes exactly what that means and is it only in regards to labor for Apple devices, or are these skills different.

Also, I’d like to know more about Apple’s “Training Academy”. If you already written about it, please point me to it!

What are these mystery skills that Americans are unable to acquire. Is it the tediousness of small parts assembly that makes it unattractive? How much is automated??

Wes, you are exactly on target. If you are curious you will want to look at t5he Lowell experiment in the 19th century in Mass.

or perhaps the Pullman era in Chicago.

In the words of Rocky. Squirrel, "that trick never works"

Please read them before you post, especially if you can't see your post anymore, otherwise you're just wasting your own time.

Cook's and Jobs' quotes are pretty clear.

It beats me why AppleInsider would have a point of view about seeing manufacturing in the US. It makes AI an unreliable reporter on the issue. What if every large country or trading bloc followed similar strategies to make sure everything sold was manufactured domestically? If businesses literally had no other choice but to follow these imposed rules they would spend all of their investment on regionalised production rather than R&D on innovative new products - assuming, of course, they didn’t simply want to forgo those other markets because the local manufacturing requirements were too draconian to care to participate.

For most of your complaints, they are addressed in this and other texts we've already written. Cost-infeasible is clearly in the piece. So is the time clock on the Trump administration.

Also, incidentally Apple's Mac Pros are made here in Austin. The notion that Apple is not manufacturing here is incorrect. Maybe it's not at at the scale people like, yet, but it's something.

From Apple about Austin: "Meanwhile, construction continues on Apple’s second campus in Austin. Apple has more than 13,000 team members across Texas, including thousands already working from the three completed office buildings, which exceed 1 million square feet. The three buildings currently under construction include an expansive new R&D lab space for Apple’s Hardware Engineering, Hardware Technology, and Software Engineering teams."

A small percentage of Mac Pros are made in Texas still, but they're mostly overseas now, starting with Apple Silicon.

Texas is covered in the piece, and like you said in the point you were trying to make, it is not a new announcement. Samsung is also an existing partner, and has been for over 20 years. This iPhone image sensor thing is a three-year old rumor, isn't new, and the sensors will be shipped to India and China for assembly.