Carbon fiber inserts could create ultra-thin MacBook display

The MacBook Pro could take advantage of carbon fiber to strengthen the display in the future, using the inserts to minimize damage to the screen from flexing the notebook's top section, without adding any significant weight to the portable device, while also making it extremely thin.

By the nature of being designed for moving from one location to another and for working while on the move, notebooks like the MacBook Pro aim to be as light as possible while still being strong. However, the pursuit of sacrificing weight can turn into a reduction in strength.

One of the main casualties of this tradeoff are displays, which can be subjected to torsion effects from twists of the display lid, which is usually kept as the thinnest section of the notebook's body, and so contains the least material. Over time, the twisting of the lid could weaken the display itself, causing it to crack.

In a patent granted to Apple by the U.S. Patent and Trademark Office on Tuesday titled "Electronic devices with thin display housings," it is suggested the use of carbon fiber could be employed to enhance the strength of that section.

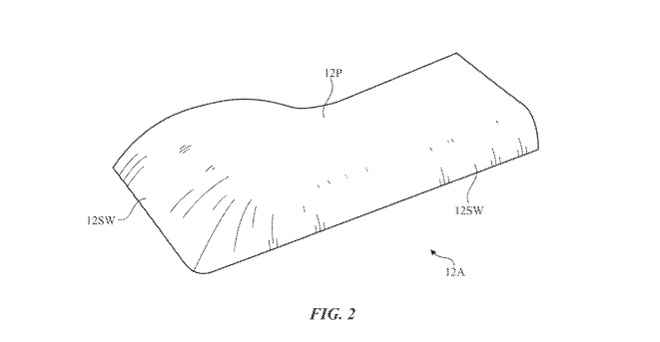

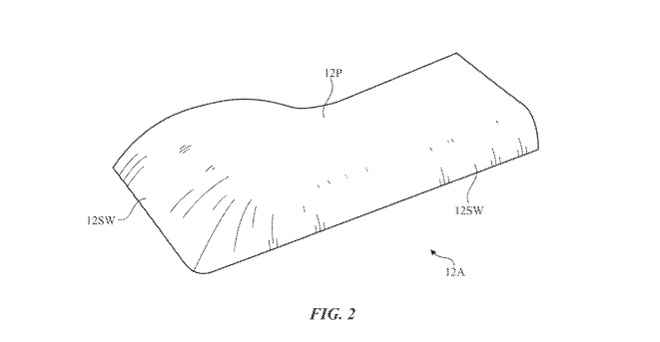

The claims of the patent indicate the use of a housing with a planar housing wall portion that uses a "carbon fiber composite material," possibly as part of a woven fabric which includes a polymer binder. The carbon fibers are said to run through the panel at such angles that it is not parallel to either the vertical or horizontal edges, minimizing the possibility of offering a convenient point for folding or creasing.

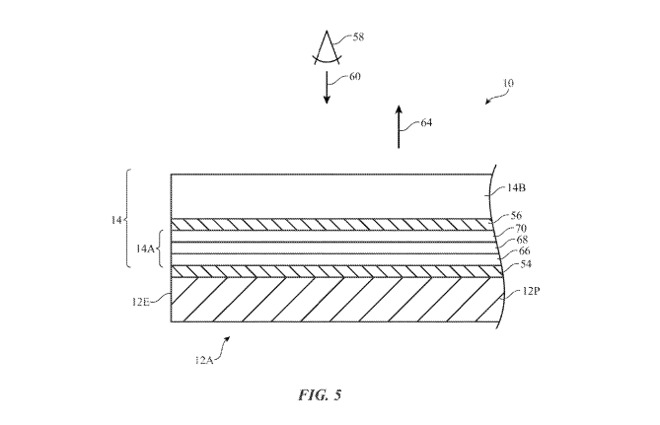

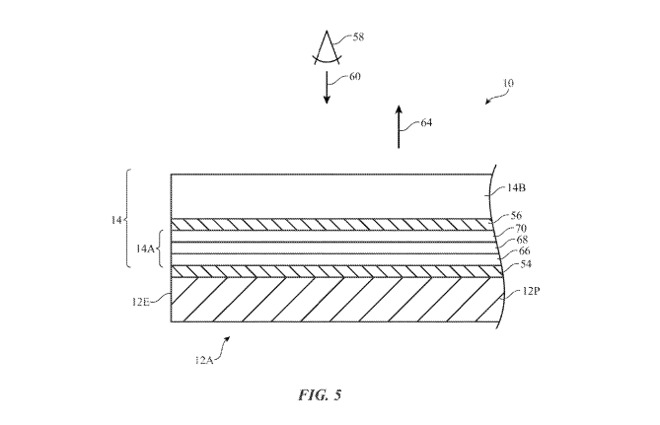

The stack of layers, with a protective layer at the top followed by other layers for the polarizer, OLED panel, substrate, housing wall, and rear cover.

The housing wall is covered on one side by a display cover layer, giving it the external appearance desired for the product. On the other side is an OLED display that attaches to the housing wall using multiple layers of adhesive, though it is also possible the display could be attached to a glass substrate that in turn is glued to the wall.

A polarizer can then be attached to the display or the display cover layer, again with adhesive to improve strength. Both the housing wall and display cover layer could also have a curved sidewall, which can help make the panel more rigid.

Apple's belief in the strengthening capabilities of the combination leads it to believe it could be used to make extremely thin display panels, far thinner than currently offered. It is suggested the housing and display could have a combined thickness of "less than 2mm," making it one of the thinnest displays ever if it is actually put into production.

An example of a curved wall and corner used to improve rigidity of panels

Apple files numerous patents and applications on a weekly basis, but while the presence of a patent may suggest areas of interest for Apple's research and development teams, it does not guarantee the concepts described will make an appearance in a future product or service.

In this case, while it seems plausible for Apple to actually put the technique into practice, given its penchant for designing ever-thinner devices, it may be quite a while before manufacturing techniques catch up to a point of reliability where Apple is prepared to use it in a future MacBook.

Apple has, however, used a similar technique in the past to maintain strength while reducing weight. For the Powerbook G4, Apple used a combination of a carbon fiber frame and a titanium wrap to make it as light as possible.

The push for thinner devices has recently led Apple to consider alternate ways to reduce the keyboard's thickness. In one patent, Apple proposes eliminating the butterfly mechanism in favor of a switch design that cuts the thickness further, allowing for either more space inside the lower section for more battery capacity or for an overall reduction in thickness.

Another patent proposed another switch design that used the blockage of light when a key is pressed for inputs, rather than traditional switches, again potentially reducing the keyboard's thickness.

The carbon fiber system could also be employed for another concept Apple has considered, where the keyboard is entirely replaced by glass panels and touch-sensitive displays.

By the nature of being designed for moving from one location to another and for working while on the move, notebooks like the MacBook Pro aim to be as light as possible while still being strong. However, the pursuit of sacrificing weight can turn into a reduction in strength.

One of the main casualties of this tradeoff are displays, which can be subjected to torsion effects from twists of the display lid, which is usually kept as the thinnest section of the notebook's body, and so contains the least material. Over time, the twisting of the lid could weaken the display itself, causing it to crack.

In a patent granted to Apple by the U.S. Patent and Trademark Office on Tuesday titled "Electronic devices with thin display housings," it is suggested the use of carbon fiber could be employed to enhance the strength of that section.

The claims of the patent indicate the use of a housing with a planar housing wall portion that uses a "carbon fiber composite material," possibly as part of a woven fabric which includes a polymer binder. The carbon fibers are said to run through the panel at such angles that it is not parallel to either the vertical or horizontal edges, minimizing the possibility of offering a convenient point for folding or creasing.

The stack of layers, with a protective layer at the top followed by other layers for the polarizer, OLED panel, substrate, housing wall, and rear cover.

The housing wall is covered on one side by a display cover layer, giving it the external appearance desired for the product. On the other side is an OLED display that attaches to the housing wall using multiple layers of adhesive, though it is also possible the display could be attached to a glass substrate that in turn is glued to the wall.

A polarizer can then be attached to the display or the display cover layer, again with adhesive to improve strength. Both the housing wall and display cover layer could also have a curved sidewall, which can help make the panel more rigid.

Apple's belief in the strengthening capabilities of the combination leads it to believe it could be used to make extremely thin display panels, far thinner than currently offered. It is suggested the housing and display could have a combined thickness of "less than 2mm," making it one of the thinnest displays ever if it is actually put into production.

An example of a curved wall and corner used to improve rigidity of panels

Apple files numerous patents and applications on a weekly basis, but while the presence of a patent may suggest areas of interest for Apple's research and development teams, it does not guarantee the concepts described will make an appearance in a future product or service.

In this case, while it seems plausible for Apple to actually put the technique into practice, given its penchant for designing ever-thinner devices, it may be quite a while before manufacturing techniques catch up to a point of reliability where Apple is prepared to use it in a future MacBook.

Apple has, however, used a similar technique in the past to maintain strength while reducing weight. For the Powerbook G4, Apple used a combination of a carbon fiber frame and a titanium wrap to make it as light as possible.

The push for thinner devices has recently led Apple to consider alternate ways to reduce the keyboard's thickness. In one patent, Apple proposes eliminating the butterfly mechanism in favor of a switch design that cuts the thickness further, allowing for either more space inside the lower section for more battery capacity or for an overall reduction in thickness.

Another patent proposed another switch design that used the blockage of light when a key is pressed for inputs, rather than traditional switches, again potentially reducing the keyboard's thickness.

The carbon fiber system could also be employed for another concept Apple has considered, where the keyboard is entirely replaced by glass panels and touch-sensitive displays.

Comments

Every product is designed around various "budgets," be it sizes (total size, screen size, etc.), weight, thermal dissipation, run-time on battery, physical durability (e.g., drop test), computing power, etc. As a product designer, when you consider how you spend your budget in one area you usually have to make trade-offs that affect other areas. The screen is a good example of a function that is almost totally defined by the display surface that it presents to the user. I'd imagine the full function of the screen as a display surface could be rendered in something a few micrometers thick. But to support other functions, qualities, and contribute to their budgets and required attributes, like durability, it has to be thicker. But if the screen and its supporting structure could be ultra thin it would also free up weight budget that could be applied to making the battery a little heavier to improve run time or add a keyboard with more key travel.

Bottom line - all products from smart phones to commercial passenger jets require compromises that affect many quality, functional, and cost factors and attributes that materially impact the final product that ends up in the customer's hands. Each factor and attribute has a budget and someone has to make intelligent decisions about how to spend these budgets to achieve the desired product capabilities, qualities, and attributes in the finished product. Apple is a pretty smart company when it comes to figuring out how to spend their budgets to achieve highly desirable and functional products that delight hundreds of millions of customers. Could they have possibly overspent in some areas while underspending in others? Perhaps. But someone had to make the call and finalize designs that could be manufactured and deployed to customers within a time and cost budget using the tecniques and technologies aavailable to them at the time. Nothing Apple does is arbitrary, ephemeral, or superficial, so every time they have an opportunity to embark on a new product design or tweak an existing product design, they are absolutely going to revisit their budgets and try to leverage new techniques and technologies to achieve an even better aggregate product the next time around.

My point is that you travel folk don't need a MacBook Pro. You need a powerful AIR. Apple should run the AIR over with a road roller to satisfy you, since you'd just as soon type on glass to make your fingers feel good so long as it made your travels happier. But The Rest of Us don't travel on aircraft daily and because of that we want:

Thicker

More Key Travel

Bigger Battery

Better Cooling

ENOUGH SAID.

To be blunt, you are absolutely wrong! With your logic why improve on anything. I tell my kids, you should always strive to improve on all aspects of your life and work. Instead of settling for mediocrity. With your mentality, as a species, we would not advance very far. Amazing to see the “good enough crowd” is still around.

Specifically regarding the lighter material “you go Apple you go.” Further, we won’t know how this material will work until after it’s implemented and can experience the benefits.

It seems as if the Mac fans here are unaware of how Apple computers (not their other stuff, I believe, and certainly not Apple’s “services”) are losing market share, and seriously irritating their user base. The reason: they’re no longer the top-tier products they used to be, which were worth the price. The innards are no longer bestest/fastest/most robust, and the capabilities have not just not kept up, they’ve depreciated. Better, more capable computers can be had for less from Windows competitors. Probably many factors are behind this - the thinness obsession, the iOS-likeness come first to mind - but it’s certainly not because they’re more attractive. Me? I still like my years-old MacBook Air, but much as I’d like something newer and more capable from Apple, there’s not currently a MacBook I’d want to have, most especially at the price they’re asking. I’m also very disappointed at Apple’s quality control, my impression being that consumers are increasingly being used as beta testers. Finally, Catalina’s a deal-breaker for me, too.

The iPhone 11 is already 8mm thick and is very elite-friendly, calm down.

Having one of the biggest failures in Apple as your profile picture really speaks for itself.

But anyway:

We're not against having a thicker laptop.

We're not against having a thicker laptop.

We're not against having a thicker laptop.

Having a patent to shrink the display has nothing to do with the overall design.

Having a patent to shrink the display has nothing to do with the overall design.

Having a patent to shrink the display has nothing to do with the overall design.

(This is the biggest font, if you still can't see then I don't know what to do.)

Period. iPhone is getting thicker, MacBook Air is a whole lot thicker for its performance, and the Pro will do the same when it's necessary, which I think is about time.

Key Travel has nothing to do with your wish, it is about having a new experience first rather than reducing the size of the machine. Not everyone likes it and some hate themselves for liking it, but your performance can still be stronger with it. You're hallucinating, simply because you saw the word "Thin" would give you a panic attack, without having any reasonable thoughts of the technology itself. My advice, go learn how computers work before judging things like some kind of KOL.

This is why KOL is garbage today because they're Hallucinating. Go brag about it somewhere else when it covers topics like this, not the Patents where it's still just a concept!! AND IS ABOUT THE DISPLAY ONLY!

There needs to be about 5 mm of bezel, if no notch is desired, but having a bump won’t be a problem. When closed, there would just be a recess on the other side, like it is recessed already for opening the lid.

I definitely think they can make an A13X laptop that is 12 mm thick, has 5 mm of key travel, and would be as performant as a 6-core Intel. GPU would be middling though.

They just need to have more product lines for the laptop. Split it into consumer, prosumer and workstation categories.

But the separation between Pros and Consumers aren't always that clear, if people simply going for the best, they'll choose the Pro no matter what. I don't think those people care that much when the Best in the line is millimeters thicker.

To me, if the iPhone could get thicker over time, then no reason a Pro won't do it. But those KOLs in our forum have developed some kind of conditioned response when they saw the word "thin", regardless of what and how.

https://www.youtube.com/watch?v=7IV_POG0YFk