Apple Car research focusing on use of Tesla-style induction motor

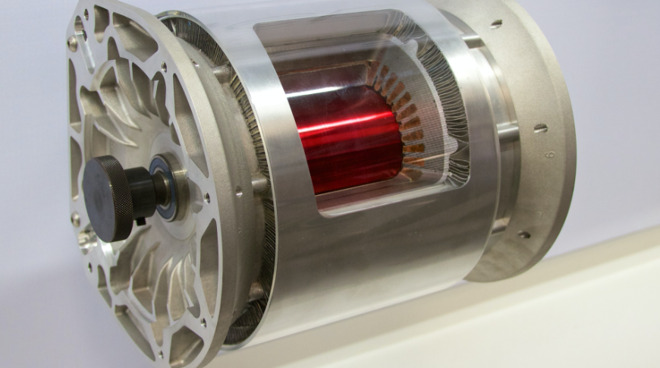

Apple is working on a three-phase AC induction motor suitable for an Apple Car, implementing the same basic engineering and motor design principles that Tesla uses.

Apple will still not say that it is making a car, despite filing legally-required documentation, and also countless patents regarding the interior and exterior. Now, though, those countless patents include one that details how Apple intends to use an electrical motor that is designed for cars.

Titled "Electric motor with bar wound stator and end turn cooling," US Patent No 10,630,127, discusses the technology that Apple has chosen, and has now been granted, for a potential Apple Car.

The patent details specifically a three-phrase AC induction motor, which is only one of several possible electrical motor systems for cars. However, it uses the same squirrel cage motor technology that Tesla does.

Apple will have chosen this technology specifically for the same reasons that Tesla has. It can generate a high starting torque when the voltage/frequency is controlled, it's cheaper, and is also useful over rugged terrain. These motors can be also be expected to have a longer life, and need less maintenance, than, for instance, a permanent magnet drive.

In comparison, hybrid vehicles from Ford and Nissan use permanent magnet synchronous motors. They are more efficient than induction motors, but they also cost more and need greater maintenance. Plus their magnets tend to wear out and need replacement over time.

Three-phase induction motors are likely chosen because the technology is relatively cheap to build, requires little maintenance, and can generate a high starting torque when voltage/frequency is controlled. When properly controlled, a three-phase AC induction motor can be made to be 90% efficient. The problem is in the complexity of that control, though the patent does not explicitly detail Apple's systems for handling this.

Instead, Apple's patent concentrates on the motor technology paired with a method for dissipating heat from the engine. "[A] cooling structure [is] disposed in a thermally conductive relationship with at least one of the upper exterior ring surface or the lower exterior ring surface for receiving heat from the end turn ring," it says.

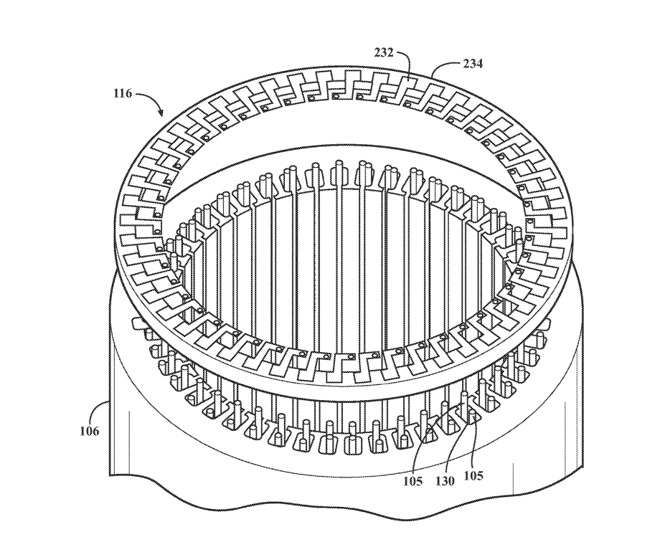

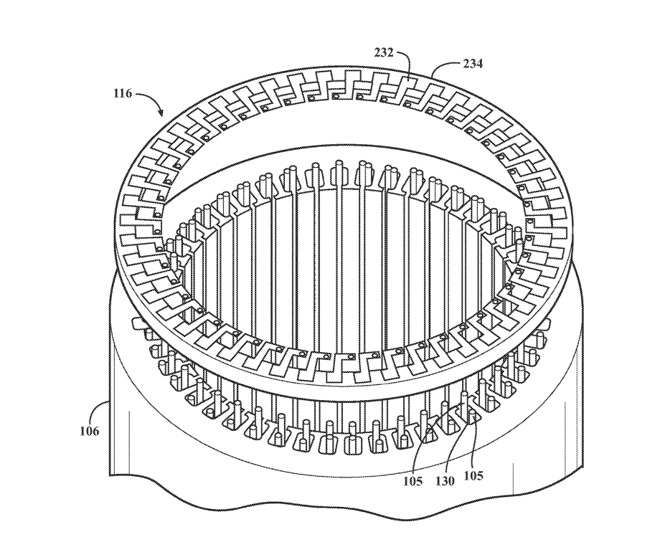

Detail from the patent showing a three-phase AC induction motor

The patent is credited to five inventors, Dillon J. Thomasson, Kan Zhou, Rui Guan, Yateendra B. Deshpande, and William M. Prince. Thomasson, Zhou, and Guan are all previously credited on the related patent "Electric motor with shielded phase windings."

Apple will still not say that it is making a car, despite filing legally-required documentation, and also countless patents regarding the interior and exterior. Now, though, those countless patents include one that details how Apple intends to use an electrical motor that is designed for cars.

Titled "Electric motor with bar wound stator and end turn cooling," US Patent No 10,630,127, discusses the technology that Apple has chosen, and has now been granted, for a potential Apple Car.

The patent details specifically a three-phrase AC induction motor, which is only one of several possible electrical motor systems for cars. However, it uses the same squirrel cage motor technology that Tesla does.

Apple will have chosen this technology specifically for the same reasons that Tesla has. It can generate a high starting torque when the voltage/frequency is controlled, it's cheaper, and is also useful over rugged terrain. These motors can be also be expected to have a longer life, and need less maintenance, than, for instance, a permanent magnet drive.

In comparison, hybrid vehicles from Ford and Nissan use permanent magnet synchronous motors. They are more efficient than induction motors, but they also cost more and need greater maintenance. Plus their magnets tend to wear out and need replacement over time.

Three-phase induction motors are likely chosen because the technology is relatively cheap to build, requires little maintenance, and can generate a high starting torque when voltage/frequency is controlled. When properly controlled, a three-phase AC induction motor can be made to be 90% efficient. The problem is in the complexity of that control, though the patent does not explicitly detail Apple's systems for handling this.

Instead, Apple's patent concentrates on the motor technology paired with a method for dissipating heat from the engine. "[A] cooling structure [is] disposed in a thermally conductive relationship with at least one of the upper exterior ring surface or the lower exterior ring surface for receiving heat from the end turn ring," it says.

Detail from the patent showing a three-phase AC induction motor

The patent is credited to five inventors, Dillon J. Thomasson, Kan Zhou, Rui Guan, Yateendra B. Deshpande, and William M. Prince. Thomasson, Zhou, and Guan are all previously credited on the related patent "Electric motor with shielded phase windings."

Comments

there are special “inverter duty” motors for this purpose, because motors don’t like to run off their designed frequency of either 50 or 60 Hz. If they do, they get too hot. The VFD will then shut them down. So while a drill press can use a regular (cheaper) 3 phase motor with this, its very disconcerting to have the mill or lathe shut off in the middle of a long cut.

this technology the article is taking about is almost the exact same technology we use. But our equipment isn’t meant to be bumping along the road while in use.

Can't wait for that Apple Car launch

According to Tesla’s Chief Motor Designer, Konstantinos Laskaris:

“So, as you know, our Model 3 has a permanent magnet machine now. This is because for the specification of the performance and efficiency, the permanent magnet machine better solved our cost minimization function, and it was optimal for the range and performance target.”

Although permanent magnet motors are more expensive from a material content standpoint, they are also more efficient due to the lower I^2R losses in the rotor. This also reduces rotor heating, and may allow a reduction in the motor's overall size and weight for a given power output. The switched reluctance type of permanent magnet motor that Tesla uses in the X does require more complex electronic controls, but delivers higher efficiency in return.

There's no real limit to motor rpm in a variable frequency drive system other than the obvious mechanical constraints. (Centrifugal force increases with the square of a rotating part's radius, so beyond some size and rpm limit everything just wants to fly apart.) Tesla's Model S induction motors turns at up to 18,000 rpm, but at the other end of the size/output spectrum you can buy tiny ultra-high speed electric motors that hit 500,000 rpm or more (https://www.celeroton.com/en/products/motors.html).

Most people commute a short distance on a regular basis. I don’t having dwelling data to indicate how many of those people have houses or driveways, but if they do it’s promising. Workplace charging too.

Most of the time, our vehicles are sitting around near us.

She has a charging point in the garage but that isn't free. Neither is charging at motorway service stations (5€).

Currently tolls are free from Mon-Friday. Doesn't pay local parking fees either.

Some supermarkets have free charging but you need your own charging cable on hand.

If you live in a block, the community has to install charging equipment if a resident requests it.

HYUNDAI IONIC 100% Electric. About three years old now.

Never said it would be free (because its not). I was just making the point that they may not really be saving much in the end versus a vehicle that gets better gas milage. And if you have to recharge every 150 or so miles how is that any better than going the gas station 2x a week?